Prefab – Rebar

Rebar cages can take longer than expected to fabricate, so it’s best to construct them before any concrete work.

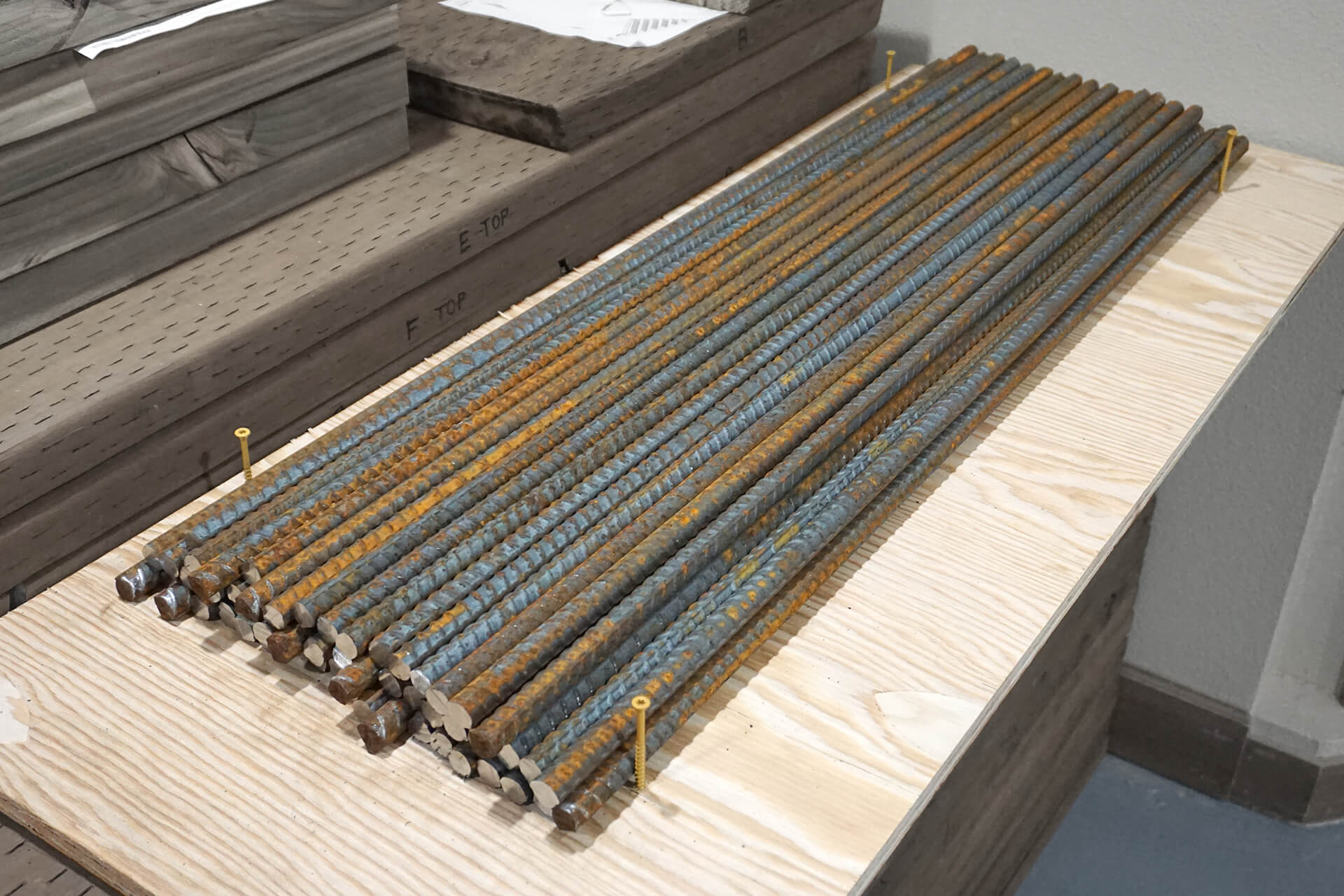

Cut the rebar to size. Using the right saw makes this task easier. The most affordable option is to use an angle grinder with a metal cut-off disc.

A stack of rebar cut to length. Minor surface rust is not a concern, as it will stop rusting once encased in the concrete’s alkaline environment.

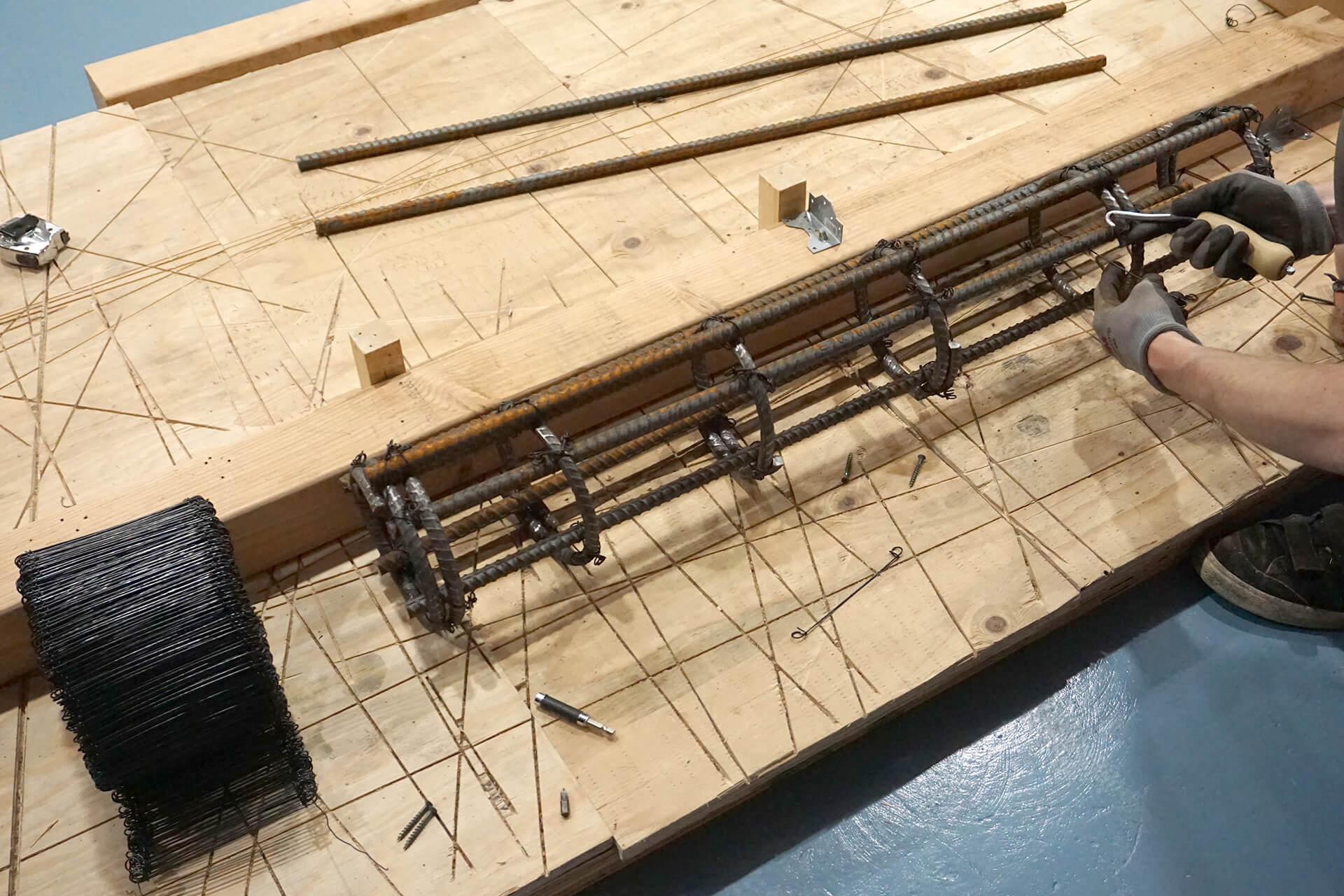

Use a rebar tying tool to attach the rebar lengths to the rebar rings. It’s simple and cheap, but very time-consuming.

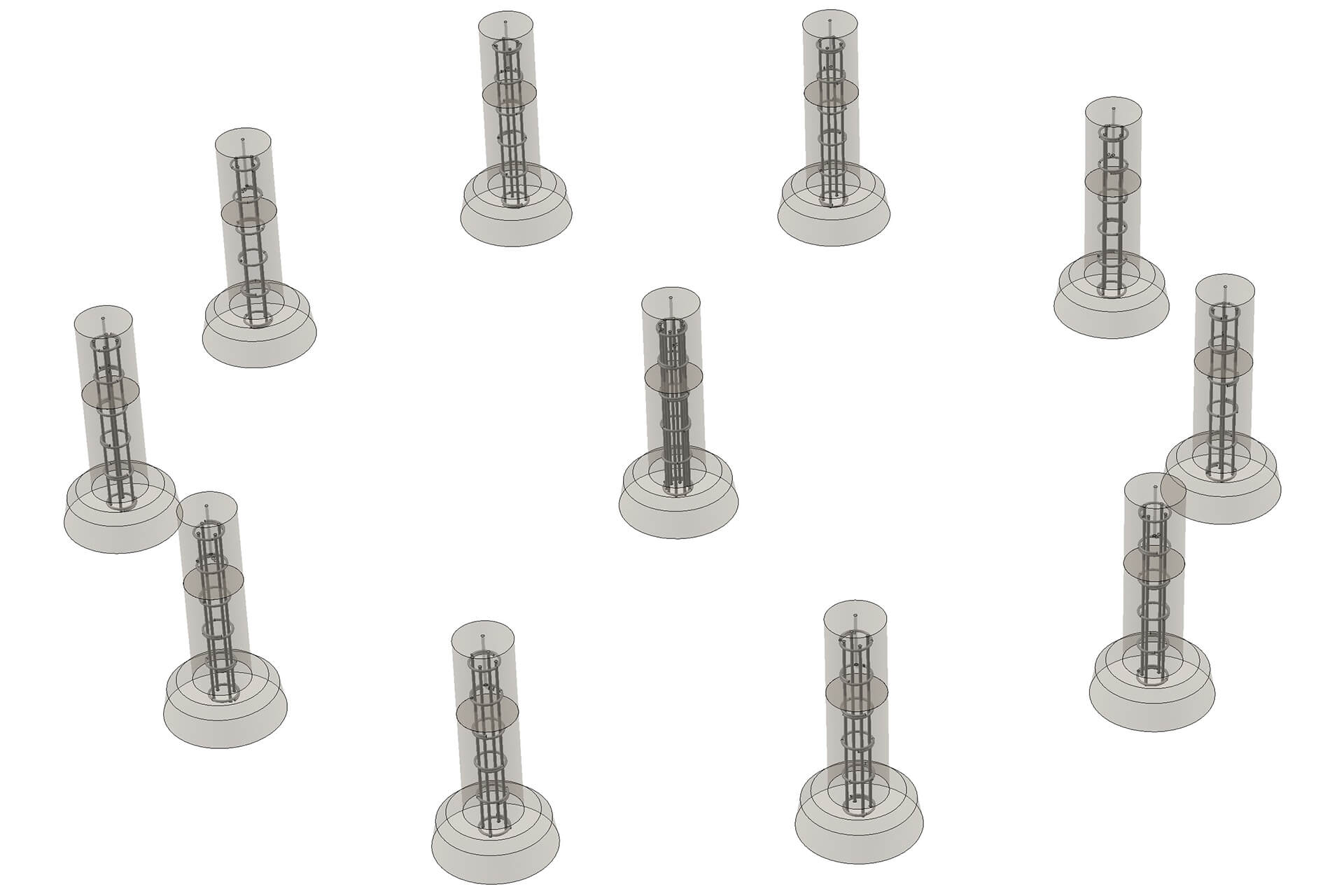

Assemble the rebar cages.

Detail shot showing what the tied rebar looks like.

A completed center pier rebar cage. The rebar cages for the outer piers require only 4 sticks each, as opposed to the 8 shown here.

Congratulations on completing the prefabrication of the rebar! Notice that the tops of all the rebar cages have doubled-up rebar rings, as specified in the drawings and often required by code.

Next Step

© 2025 Dodeca Domes. All rights reserved.