- Info

- Gallery

- Book a Stay

- Purchase

- Build Info

- Build Instructions

- FAQ

- Contact

- About

- Legal

The Perfect Dome Wall

The wall assembly follows best practices from modern building science. Joe Lstiburek, an old guy and expert in his field, popularized the "Perfect Wall" concept, emphasizing the importance of placing control layers outside the structure. With dome limitations in mind, his teachings were applied to create the perfect dome wall. Thanks Joe.

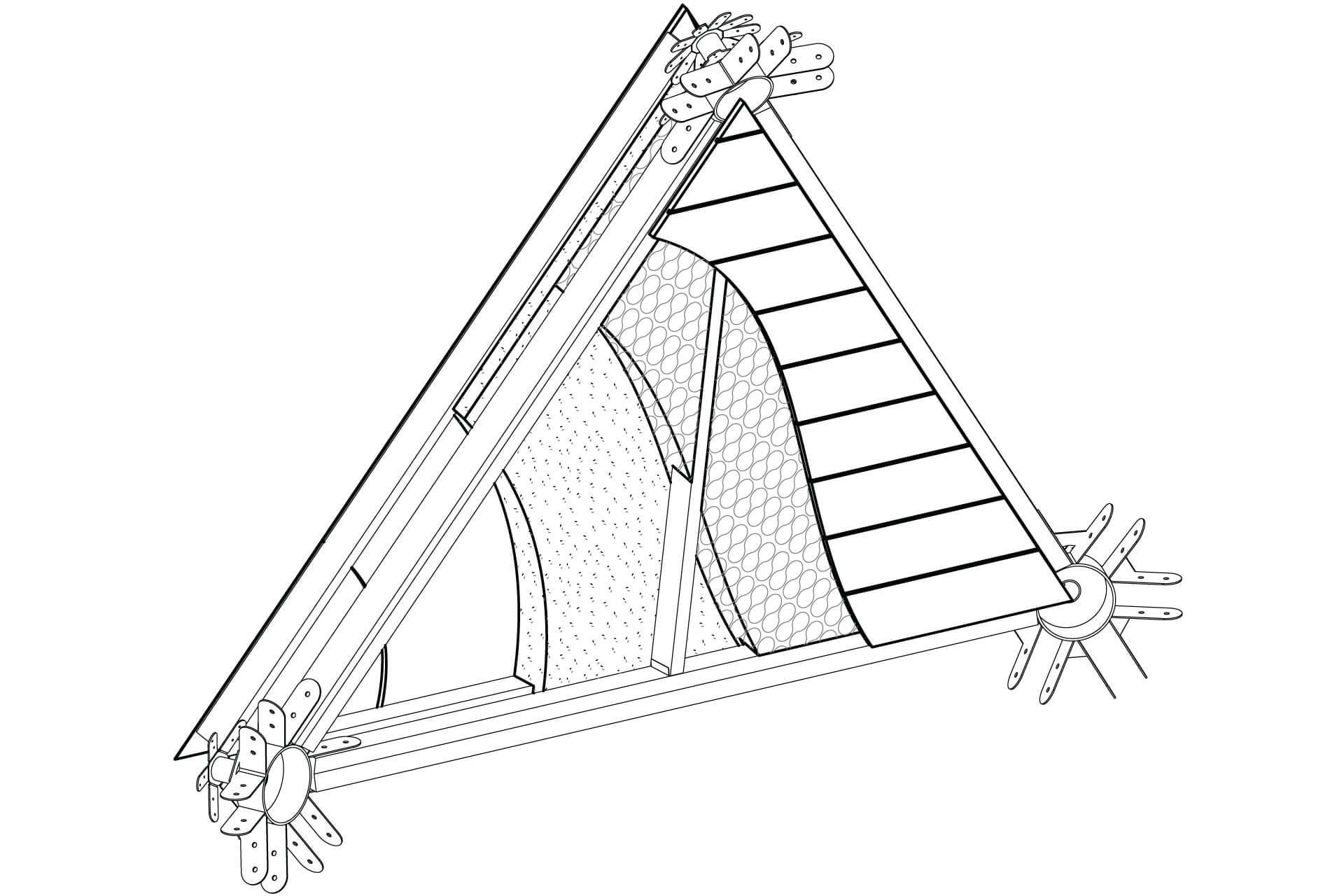

Wall assembly from outside to inside:

- Aluminum (or asphalt) shingle roofing

- Fluid-applied (or synthetic) weather-resistive barrier (WRB)

- 3/4" ACX plywood roof sheathing

- ~5.5" thick 2-lb closed cell polyurethane foam (R37)

- ~5.5" thick mineral wool (R23)

- Tongue and groove siding (or drywall)

This 1-foot thick wall is actually a double-wall, with the structural components (4x4 lumber and steel hubs) positioned on the inside, protecting them from the elements and temperature fluctuations.

The gap between the two walls is filled with insulation, acting as a thermal break to prevent thermal bridging. By conventional standards, this wall achieves an R60 rating. The floor has a similar assembly, ensuring that all control layers align perfectly.

This wall assembly is hyper-efficient and designed for all climate zones. The dream: heat it with a fart, cool it with an ice cube!

© 2025 Dodeca Domes. All rights reserved.